So I'm looking into getting a block built on the side incase the worst were to happen with my stock block. I am in no rush with this aspect of the build, but do want to start getting some parts, so if the motor were to blow, I would have minimal downtime. I also have a good bit of learning to do in this aspect, as it will be my first motor build. I copy and pasted some discussion from 8th about it, let me know your guys' thoughts!

Ok, I would like to use the type-s pump as it seems to be better especially for built motor and more revs safer. So would you suggest using our crank pulley? Or the crank pulley for the a2?

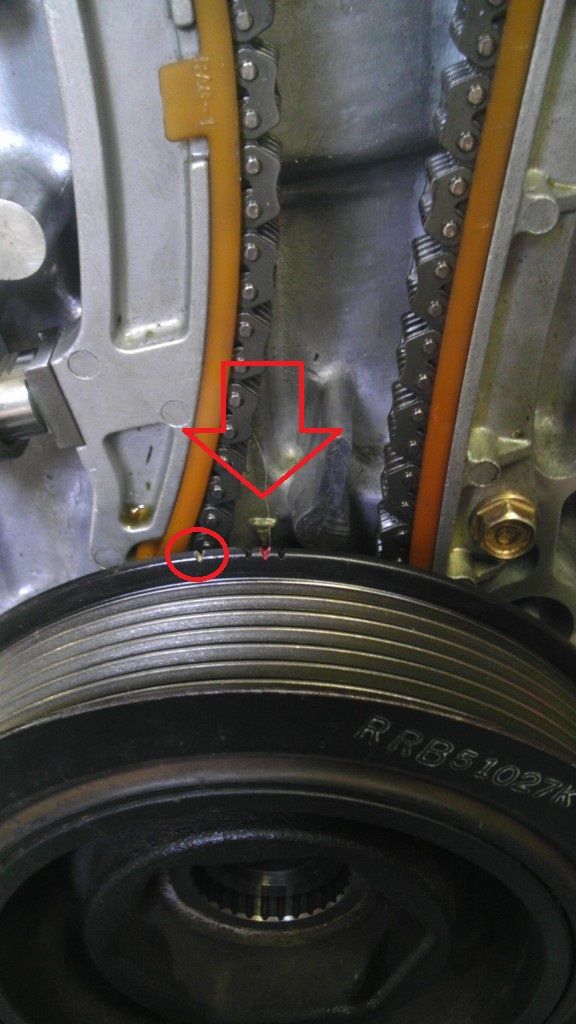

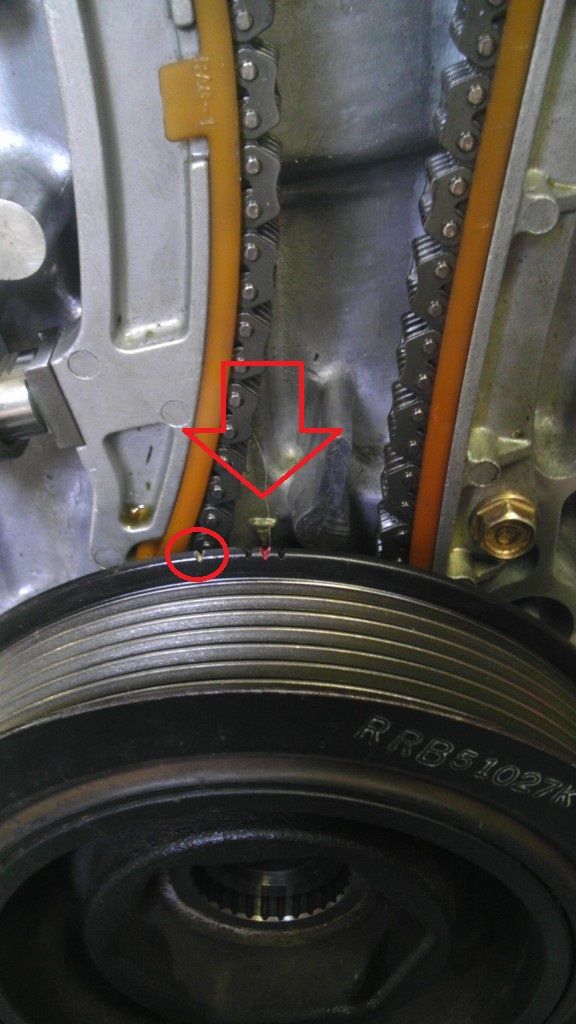

Ok, so the crank gear is going to be on the crank that I could buy with the motor? Also in the bottom picture I see the mark that is circled, but I also see 3 other marks, the middle one lines up with the arrow. What are those 3 marks originally for? Or were they added?

Ok well I just was reading this a little:

A1/2/3/4 vrs K20Z3 oil pump - K20A.org .:. The K Series Source . Honda / Acura K20a k24a Engine Forum

A lot of it is over my head, but seems the consensus is that, perhaps the z3 oil pump is actually just as good if not better than the a2 because of the balance shafts.

How much more oil do I need for the a2 pump? You're using the a2 pump, right?

Ok, well I will probably stick with a stock head, so IDK if I can even go above 8600 rpms without at least different valve train? I'm not looking for an all out monster, just a motor that I know will last a very long time at 500whp or so, and still be reliable and simple like a stock motor. I hope that is possible.

Ok, is it possible to get a valvetrain that can handle is that isn't titanium and requires replacement every 20k? And at this point in time, I don't intend to necessarily push it much harder than the stock block. I just want a block that I can have a little more confidence in.

I know what you mean. I just basically want to beef up the stock engine a tad. The stock motor is quite strong and seems to last quite a while, but I would like something that is very stock like, but has stronger internals, just so it is more designed for 450-500whp. I don't really want sleeves or crazy cams.

If possible I'd like it as reliable as the stock engine is, just stronger.

Ok, can I get higher rate springs that are not titanium and will last quite some time?

Ok, but I really am not trying to go crazy here, I just want something simple and stronger. I like the stock engine

If I knew it would last till 200k boosted I wouldn't be doing anything, but I think that's a bit of a stretch.

Yea they would, I don't even necessarily want to run 500whp, just want to be able to do 450 for a LONG time. And occasional 500+whp with race gas. Probably never going to see a turbo larger than a GT3076.

Why darton sleeves? What is Vit using? I know bulliedog has benson sleeves. How are skunk2 rods?! Why not upgrade the pistons if I'm doing all that? (legit question). Why the valve springs from an 02 type s? Could it be 02-04? What is the lb rating for the stock valve springs?

That sounds like exactly what I'd want in terms of power capability and mileage.

Thanks so much for the input.

Ok, any reason you chose the bensons over the dartons?

Ok that's really cool stuff. Sounds like a good combination. But why still stock pistons? Are aftermarket pistons less reliable?

Ok that makes sense, 75k isn't terrible. Don't I run the risk of destroying a stock piston at 20 psi for long periods of time? Or are they really THAT strong?

Also are the alpha series valve springs from skunk2 not good enough for what I want? Is that why you suggest the pro series over them?

Ok cool thanks a bunch for the input! That type of motor build sounds a bit unique, but perfect for what I want. Although I never expected to sleeve anything. O well I guess that will give me lots of peace of mind.

Are you sticking with stock cams? Would you suggest I stay with stock cams as well?

Ya I checked out his site. I just wanna know roughly what it costs. I don't want to email him yet as I am far from being ready to send him a block, just in planning stages.

OK well what do you suggest?

Hmm ok, well maybe I can just save myself a good bit of money and stick with stock sleeves. Vit in case you didn't see the discussion, I just want a built motor that is essentially as reliable as stock and will last a while like 100k miles at 450-500whp. Would the stock sleeves be ok at 86.5mm? This is what Jay suggested and I like the idea:

Shooting from the hip here, you could probably do a Darton sleeved block, Skunk2 Alpha rods, OEM pistons, OEM dual valve spring seats/retainers off an 02 RSX Type-S and Skunk2 Pro-Series valve springs in the 70lb range.

Oh geez... two major gurus arguing. Now I definitely don't know what to do lol. It seems a lot of people have success with the stock sleeves. This would very likely be on pump93 as well Vit, if that makes a difference. Only one e85 station in DE.

:cornmad: now I really don't know what to do. Will have to do more reading, and looking at the price of everything. If forged pistons will last 80k miles, or just under, that's a lot. My current engine has just under 80k miles on it and I've had the car for 6 years. So if I can get 6 years out of a built motor, that's not so bad!

What do you think about stock sleeves at 86.5mm? 10.5:1 comp?

Ok and you think stock sleeves would be ok at 86.5mm?

Ok that makes sense. Would you recommend flat top pistons? Are you regretting going with wiseco?

Ya ideally I'd stick with stock bore, but it seems when you buy an old bare block and build it, that you have to over bore it a little. Maybe I'm mistaken?

Is flat top generally more for lower compression? I would like to keep comp close to stock, like 10.5:1 as it will remain a street car entirely.

I had always thought I'd go with wiseco, but if you think JE is that much better, I see no reason why not to.

And I know this, I'd just like to increase my chances. I really like the stock motor and kinda wanna drive it till it blows, but I'd like to have something I can swap in when that happens.

This block is for sale on k20a:

It has AEBS sleeves. Anyone have any experience with these? Is this a semi-open deck design? I see the coolant ports there, but I am not totally familiar with this open deck vs. closed deck vs. semi-closed/open deck. To me this looks to be fully closed, but with coolant ports.

This is a pic Vit posted of Darton Sleeves that are semi-closed deck (is there a difference between semi-closed and semi-opened?):

And good luck, where are you moving?

And good luck, where are you moving?

Reply With Quote

Reply With Quote

Bookmarks