Originally Posted by

mnc1408

Unfortunately I have some bad news.

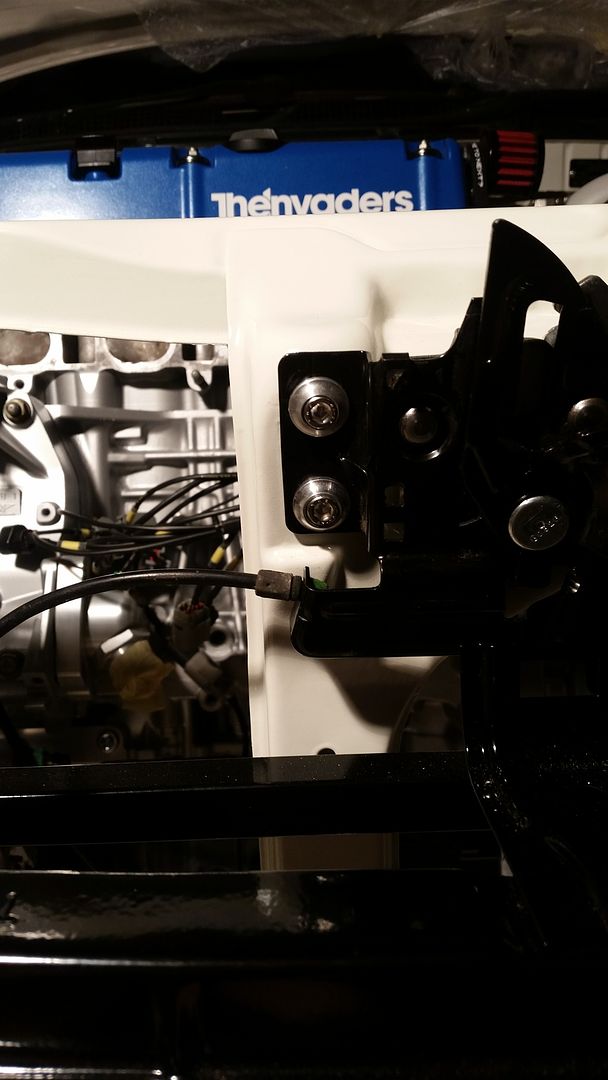

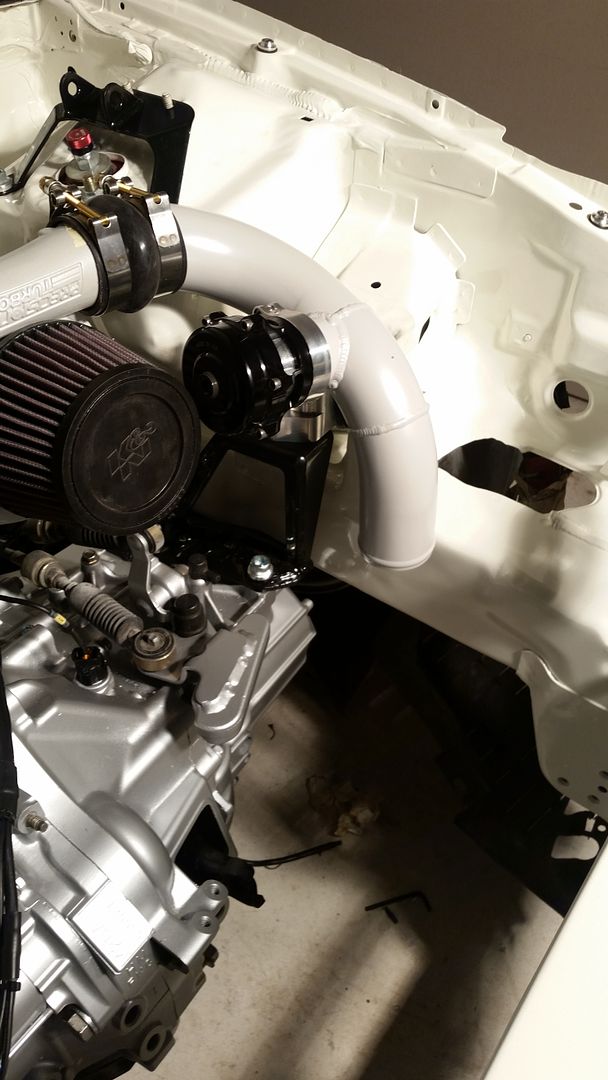

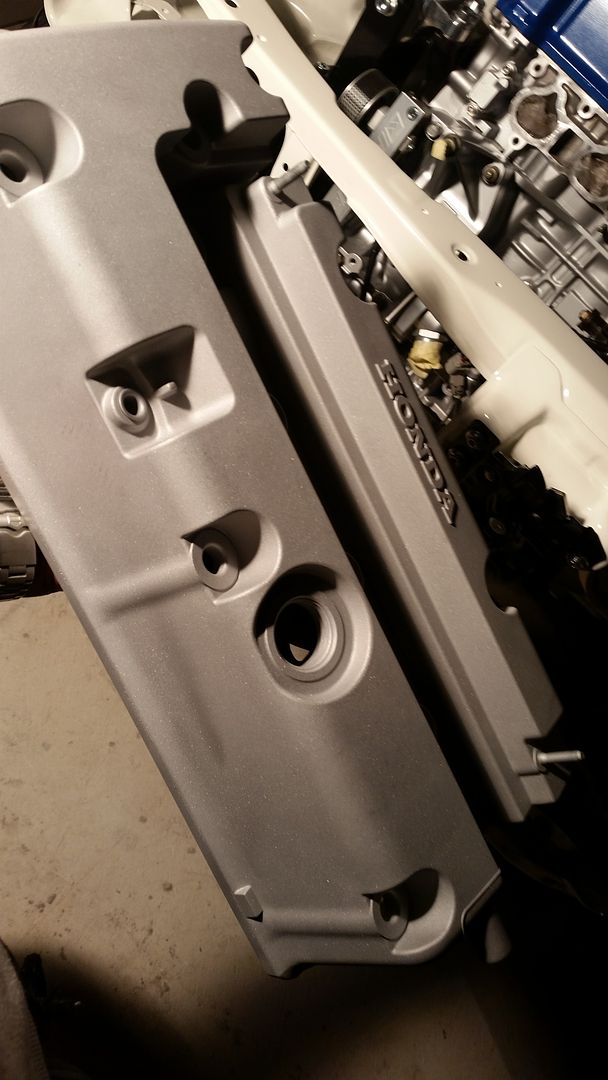

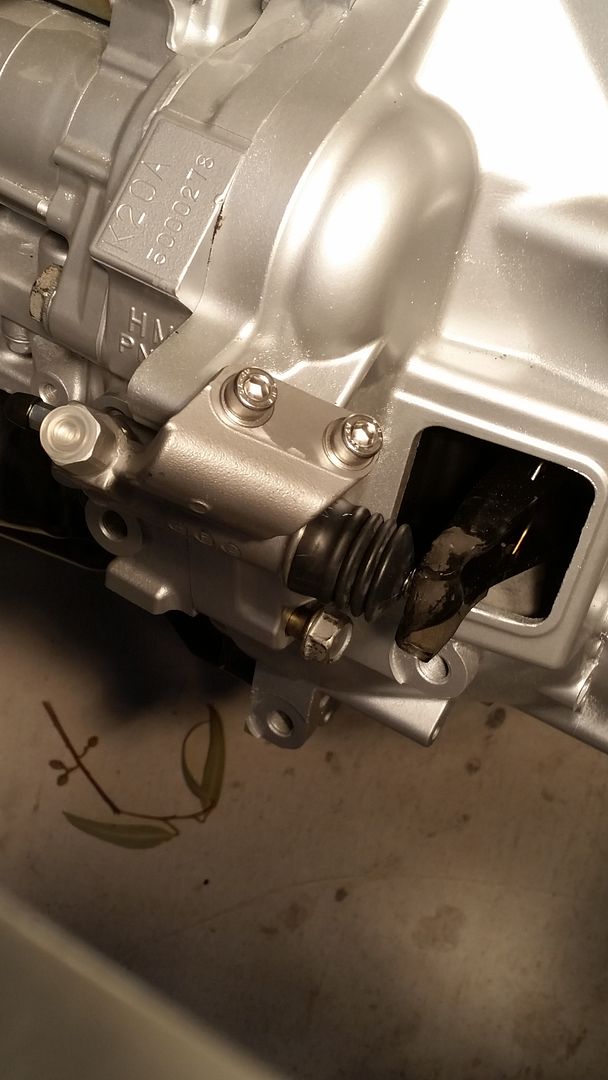

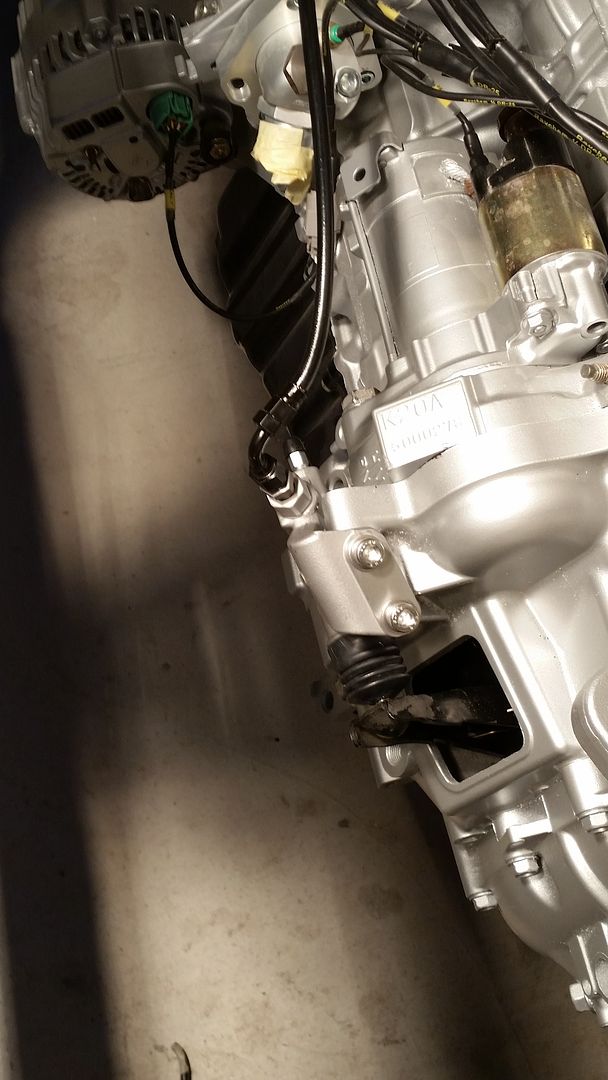

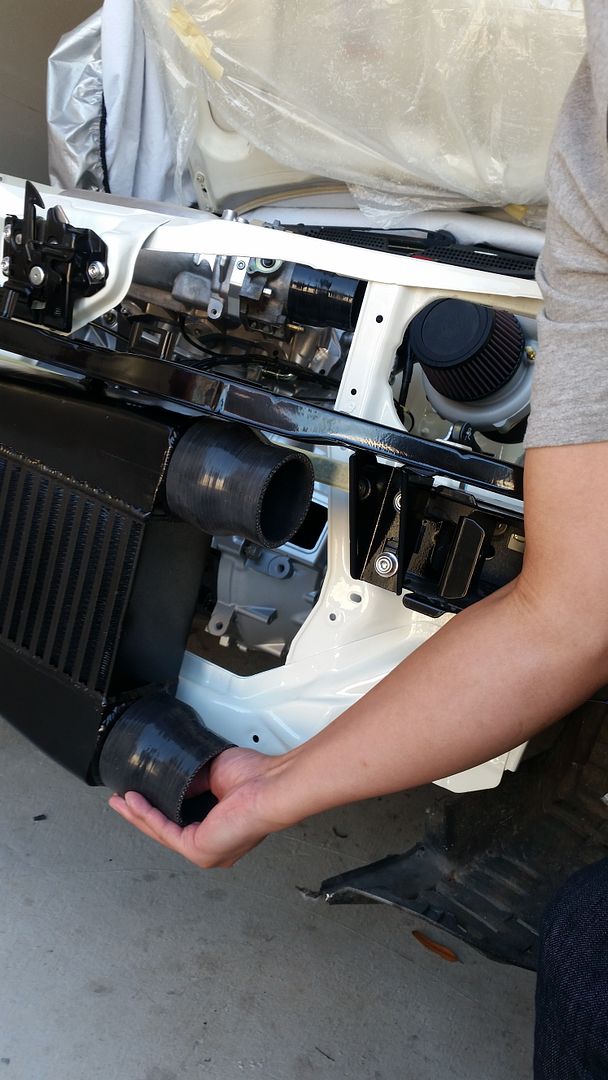

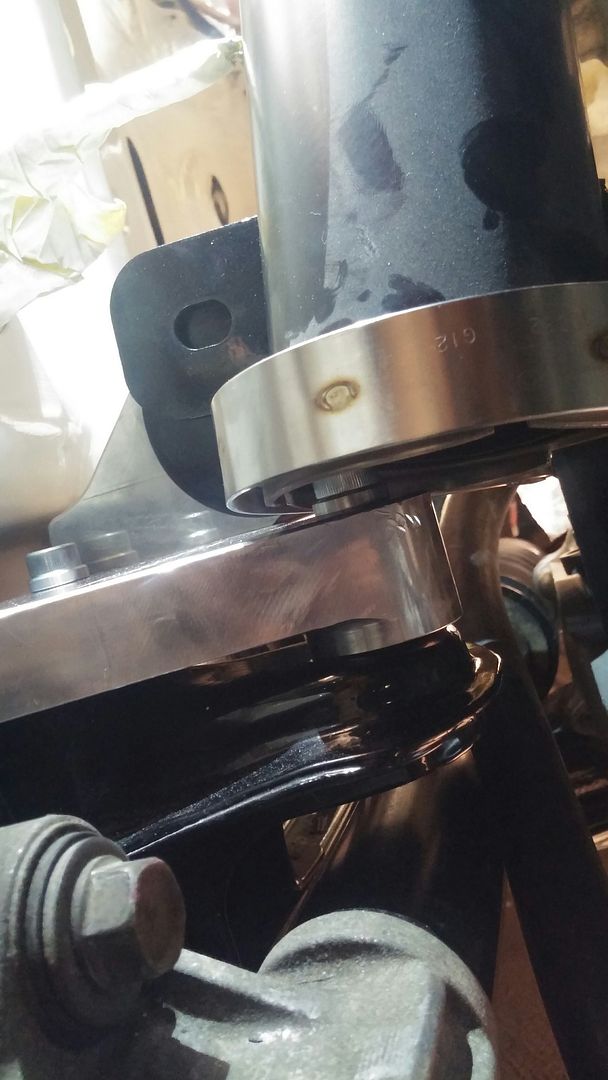

all the cooler pipings and down pipe does not fit my car.

-2 piece down pipe (looks like it will clear ep3/rsx)

-dump tube

-intercooler pipings

-intercooler inlets.

Got quoted locally $620 for cooler piping and $250 for down pipe + dump tube.

Why didn't I email JDLautodesign to fix the problem? They are fucking hiding and ignoring me, that's why.

At first they did reply, but stopped replying to the last few emails which is a little over a month now.

Any advice on how I should approach this? I live in Australia so that is just bullshit.

I sent photos etc as proof at the time of emailing.

Reply With Quote

Reply With Quote

[/URL

[/URL

Bookmarks